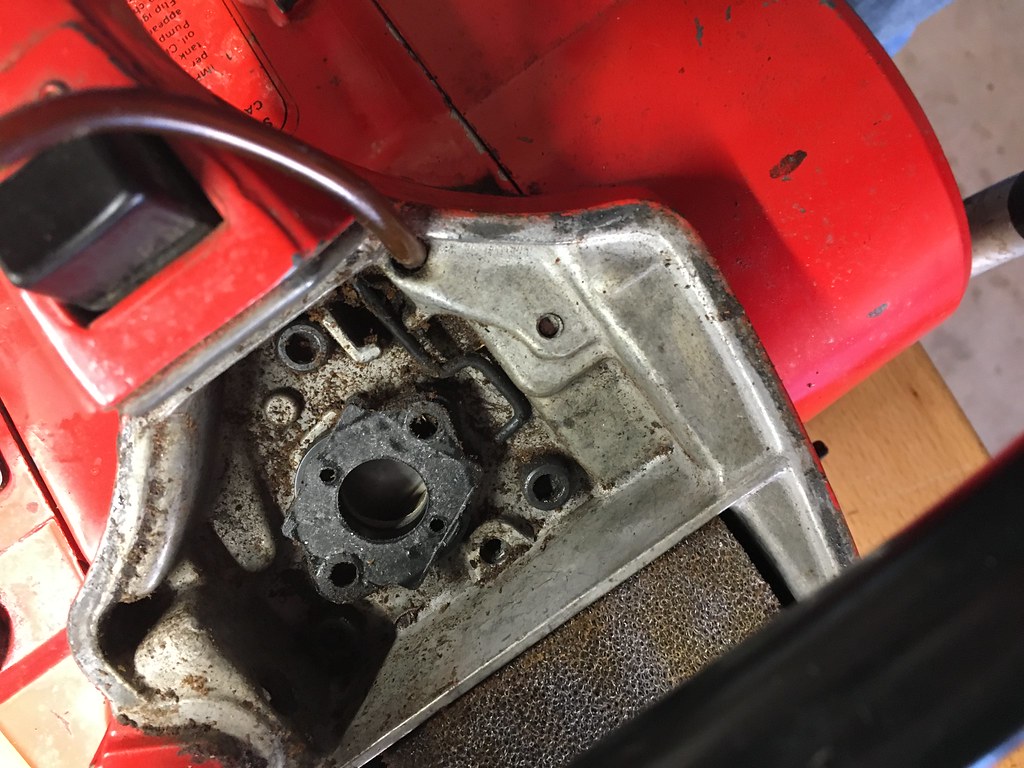

So here it is as it came. Pretty good condition really, just dirty.

drained the awful gas and sprayed out the tank some with carb cleaner. Did this s few times. To give an idea how bad it is the filter is stuck to the bottom of the tank.

back to the bench and will start cleaning it out

cleaning up really nice. I just used some gas and toothbrush and a wipe cloth

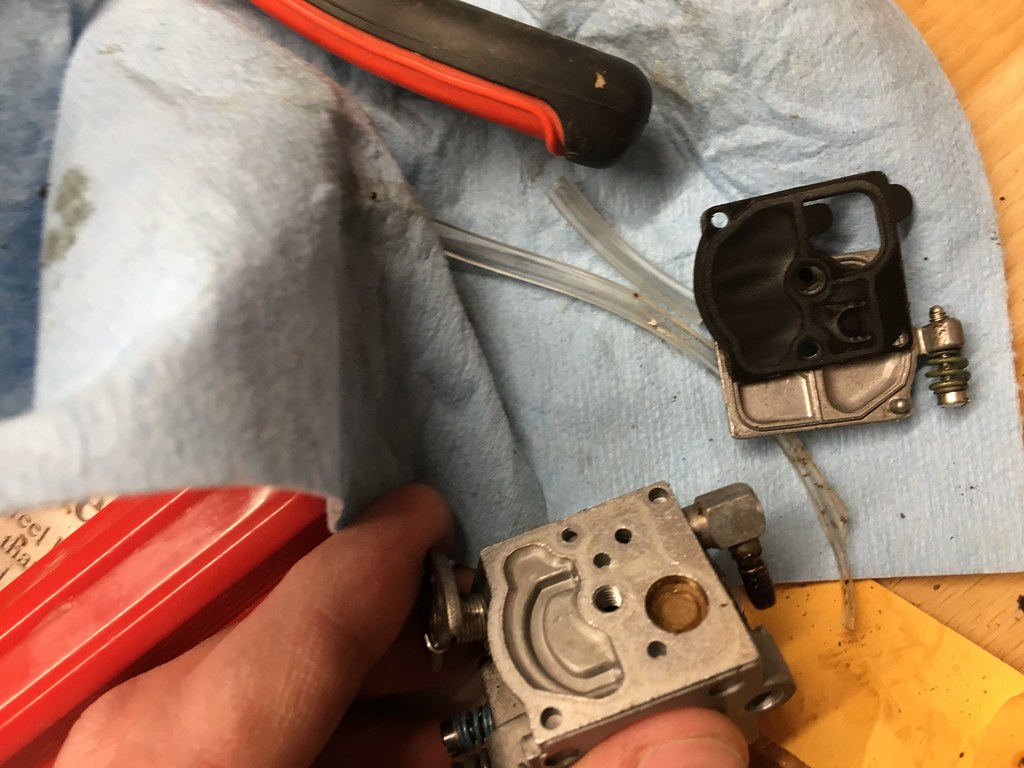

carburetor is done. The diaphragm and fuel pump are toast so I ordered a set to replace it.

First is running a new fuel line. Here you can get a sense for the hard curve it has.

The old fuel filter finally released from the tank bottom after having some gas in it for a few days...

Just for my own amusement I wanted to see if I could get this new line routed without having to take the flywheel off. So I got some 50lb. braided fishing line and a hook and double it up and ran through the old line and pulled it up through that tight curve.

So I tied off the knot and started trying to coax it through. I wish I could tell you it worked but the turn was too hard and it wasn't a continuous tube. One ended and then it had to go into another opening while making that 90 degree turn and up. It didn't happen and I decided just to see if I could pull it through with force and the knot pulled through the tube. A better know maybe would have been better. I do think this idea would work if you have a simpler routing path.

So had to take the flywheel off. I used an impact driver for this.

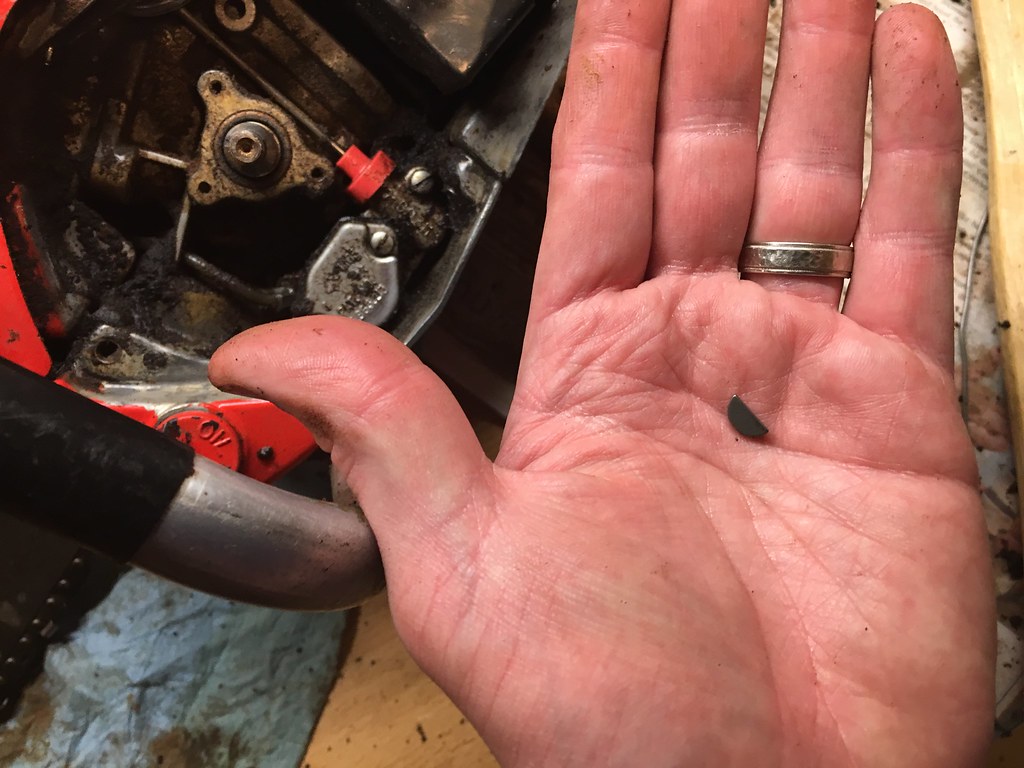

while blowing out the area first I got really lucky as a I forgot to grab the flywheel key before I started blowing. After I got done I realized it was gone and looked down and it was right by my foot. That was fortunate cause it's little and could have gone anywhere never to be found..

So routing the line was easy at this point. Hemostat pliers really make grabbing and pulling on the fuel lines easy.

Now for the carburetor. I cleaned it out and then replaced the diaphragm, fuel pump, and gaskets. All these were old and cracking.

Alright got her all put back together. Got it fired up and tuned the carb and it's running pretty good. I took it out by the wood pile to run it through a log.

Not a bad deal for a total cost of about $22

Thanks for looking folks!